Production process

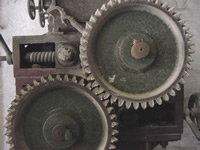

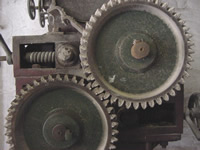

Step 1: First of all, the carefully selected malts are crushed. The selection depends on the type of beer.

Step 1: First of all, the carefully selected malts are crushed. The selection depends on the type of beer.

Step 2: Now the brewing process starts. The tailor-made brewing process determines what type of beer will be produced.

Step 2: Now the brewing process starts. The tailor-made brewing process determines what type of beer will be produced.

Step 3: Everything is pumped into the filtering vat, where it is filtered for about an hour. In the meantime, the water is heated to a temperature of about 80° Celsius to rinse the brewer’s spent grain afterwards (cauldron).

Step 3: Everything is pumped into the filtering vat, where it is filtered for about an hour. In the meantime, the water is heated to a temperature of about 80° Celsius to rinse the brewer’s spent grain afterwards (cauldron).

Step 4: The rinsing process takes an hour. During rinsing all the remaining sugars are removed from the brewer’s spent grain to increase the yield.

Step 4: The rinsing process takes an hour. During rinsing all the remaining sugars are removed from the brewer’s spent grain to increase the yield.

Step 5: Afterwards, everything is pumped into the cauldron, where it will be boiled for about an hour and a half.

Step 5: Afterwards, everything is pumped into the cauldron, where it will be boiled for about an hour and a half.

Step 6: After boiling, refrigeration takes place by means of a heat exchanger.

Step 6: After boiling, refrigeration takes place by means of a heat exchanger.

Step 7: The wort will then start the fermentation process in a fermentation tank at a temperature of about 20° C. This takes about ten days. Only as of this moment, we can speak of a young bear. In the lager tanks, the beer will mature for 4 to 5 weeks.

Step 7: The wort will then start the fermentation process in a fermentation tank at a temperature of about 20° C. This takes about ten days. Only as of this moment, we can speak of a young bear. In the lager tanks, the beer will mature for 4 to 5 weeks.

Step 8: After maturng, the beer is bottled and the kegs are filled.

Step 8: After maturng, the beer is bottled and the kegs are filled.

Step 9: The bottles are kept in a warm room for further fermentation inside the bottle for about two weeks. The beer is then allowed to rest for another few weeks before it is sold.

Step 9: The bottles are kept in a warm room for further fermentation inside the bottle for about two weeks. The beer is then allowed to rest for another few weeks before it is sold.